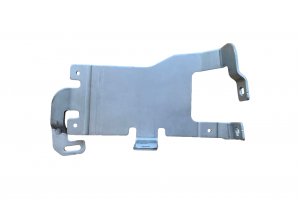

Hinge Reinforcement Plate

Part Name: Hinge Reinforcement Plate

Material Grade: CR240LA-GI50/50-U

Material Size: 2.50mm x 585mm x 264mm

Process: 800T Progression Tool

Cavity: R and L two part out

Complexity: Middle

◆Application: The part applicated to automotive hinge reinforcement part

Press Machine: 2000T hydraulic press, 1200T Mechanical

Inspection Tool: Checking fixture, CMM, Laser arm scan

Lead Time: 4 months

◆Technical Challenge: Tab condition for bracket fitment

◆Part Quality Concern: Main issue is tab condition and tab trim tolerance allowed for bracket fitment.

Background:

All two parts have x2 tabs in a closed position but we have been made aware by customer that they require 1 tab to be open for nut plate fitting. In the beginning, the bracket that fits over and is located by the tabs is very difficult fit, both tabs look to be causing an issue that is stopping the bracket from fitting over smoothly without any interference and without having to adjust the tabs. Once the bracket is located under the closed position tab it catches on the open tab, this can’t be fitted unless the tab is bent up more vertical, once steeper the bracket can then slide over and fit into position. Due to this assembly Issue, We thought we need to adjust the trim position to find a happy medium between the both the tab trim edge and the remaining trim from the slit operation. So we discussed with our customer that we need to make a further modification to improve the tab condition to allow for better assembly of the bracket, then modification data from customer sent us to show the required change point to the tab positions. In fact, there are several parts in the same project which have this similar tab condition, so the same modification for these parts with the tab geometry that we implement this into the tooling asap prior to running T3 parts. Finally, improvement of tab condition allowed for better assembly of the bracket.

Advantage:

Submit a primary project plan to customer to let them have a timetable for their project.

Control the key machining steps quality and manage the project progress according to mould processing documents, provide weekly progress and quality report to customer.

Updating regularly as customer requested with photos and videos.

If you have similar parts with tab condition for bracket fitment or any other questions, please don’t hesitate to contact me, and we are very pleased to reply and discuss with you.